Calculation of dew point

When painting on steel, you must consider the dew point temperature.

If solvent paints are used, the fog is problematic because the water is incompatible with the paint and prevents the paint from coming into contact with the steel.

With water-based paints, the fog is problematic because it forms a thin film that makes the paint thin when it comes into contact with the steel, which causes it to run easily. In addition, dew can significantly delay the drying time (water-based paint depends on the water evaporating, the water does not if vapour condenses on the surface)

Dew point temperatures are mainly a problem during the cold months of the year when the goods have been in transit in cold trucks or have been stored outdoors or in a chilly workshop, right up until the goods are taken into a heated painter's shop to have to be painted.

Dew occurs when the air is fully saturated with water vapour, and the moisture settles on surfaces that are colder than the air. Everyone knows the phenomenon when you take something cold out of the fridge in the summer; it doesn't take many seconds before the entire surface is covered with dew drops.

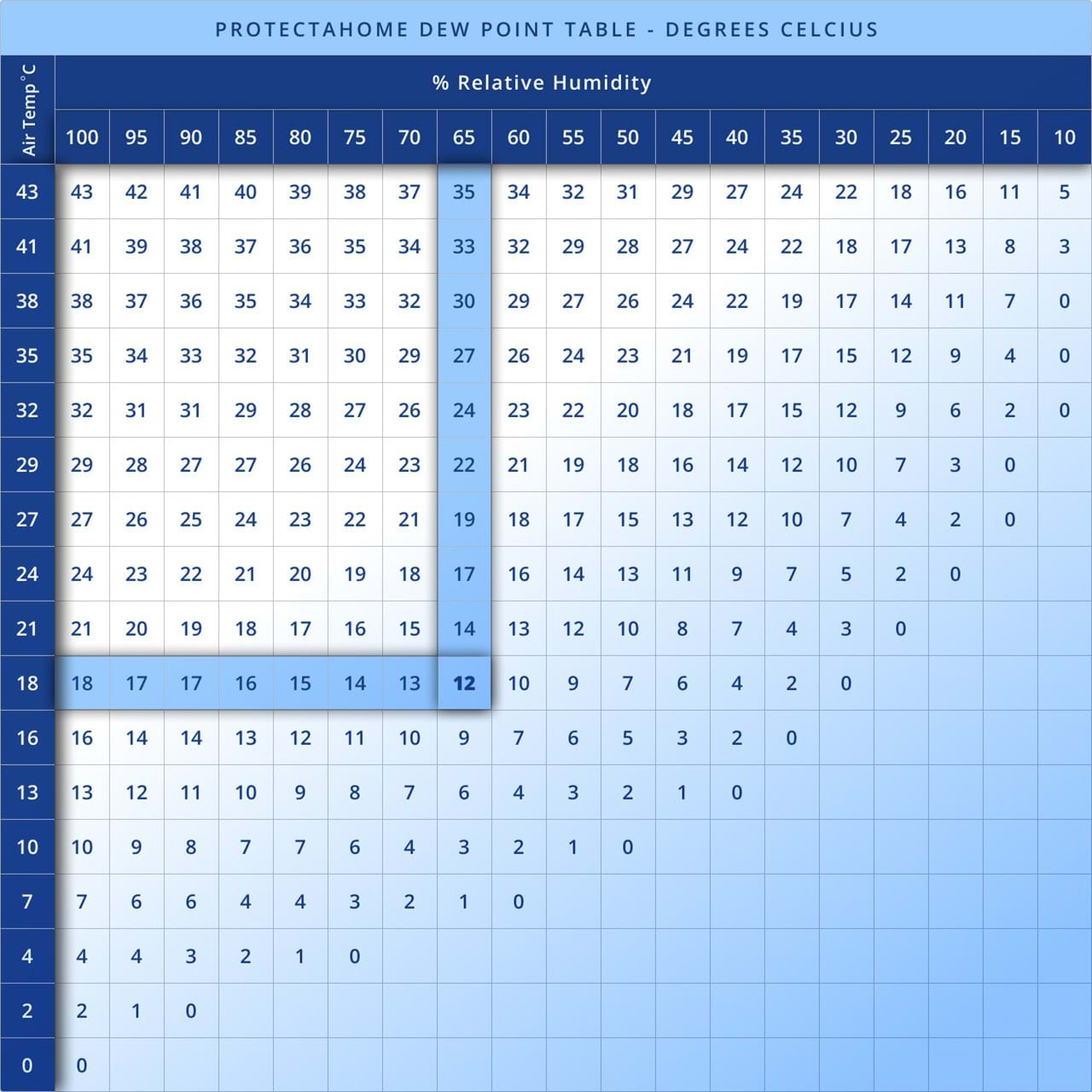

From the inserted table, you can see under which conditions this happens. It is an interaction between relative humidity and air temperature.

Let's take an example When the air is 18°C, and the air humidity (rH%) is 65, then dew forms on all surfaces with a temperature of 12°C or below. Therefore, we recommend that surfaces are painted at least three °C above the dew point, which means that the steel temperature, in this case, should be at least 15°C.

Several digital instruments measure the air temperature and rH%. In addition, they indicate the dew point temperature simultaneously (i.e. the temperature the steel should be for it to be painted). There are also devices with a temperature probe placed on the workpiece simultaneously, which thus measures whether ∆°C is three or above. The workpiece is accordingly tempered enough to be painted safely.